Skid steer loaders rank among the most versatile pieces of equipment on construction sites, farms, and landscaping operations. These compact, maneuverable machines excel at navigating tight spaces while delivering impressive lifting power. However, what truly sets skid steers apart from other heavy machinery is their ability to transform into specialized tools through interchangeable attachments.

The right attachment can turn your skid steer into a material handler, excavator, snow plow, or drilling machine within minutes. This adaptability makes skid steers invaluable for contractors and property owners who need multiple capabilities from a single piece of equipment. Understanding which attachments best suit your specific applications can dramatically improve your operational efficiency and return on investment.

Whether you’re clearing debris, moving materials, or preparing ground for construction, selecting the proper attachment ensures you complete jobs faster and more effectively. Let’s explore the most common skid steer attachments and discover how they can enhance your operational capabilities.

Buckets: The Foundation of Material Handling

Standard buckets represent the most fundamental skid steer attachment, often coming as original equipment with new machines. These attachments excel at moving loose materials like dirt, gravel, sand, and debris. However, not all buckets perform the same functions, and choosing the right bucket type can significantly impact your productivity.

General Purpose Buckets

General-purpose buckets feature a curved design with cutting edges that make them ideal for digging and loading operations. Their versatile construction handles everything from excavating trenches to loading trucks with aggregate materials. The curved bottom allows for efficient material retention during transport, while the reinforced cutting edge extends bucket life when working with abrasive materials.

High-Capacity Buckets

When you need to move large volumes of lightweight materials, high-capacity buckets deliver superior performance. These attachments feature extended sides and backs that increase carrying capacity without adding excessive weight to your skid steer. They prove particularly effective for handling mulch, wood chips, snow, and other low-density materials where maximizing volume matters more than cutting power.

Heavy-Duty Construction Buckets

Construction projects demand attachments that can withstand constant abuse from rocks, concrete, and other harsh materials. Heavy-duty construction buckets feature reinforced construction, replaceable cutting edges, and additional structural support. These buckets cost more initially but deliver superior longevity in demanding applications like demolition, cleanup, and rock excavation.

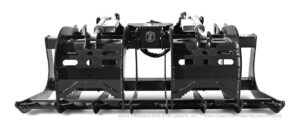

Grapples: Precision Handling for Complex Materials

Grapple attachments add mechanical fingers to your skid steer, enabling precise handling of irregularly shaped materials that standard buckets cannot effectively manage. These hydraulically operated attachments open and close like giant hands, providing a secure grip on everything from logs to construction debris.

Root Grapples

Root grapples combine the material-holding capacity of buckets with the gripping power of mechanical fingers. The solid back panel contains loose materials, while the hydraulic grapple arms secure larger items. This dual functionality makes root grapples perfect for land clearing operations where you encounter both loose soil and substantial roots or debris.

Agricultural operations benefit tremendously from root grapples when clearing fence lines, managing brush, or handling round bales. The ability to grip and precisely position materials reduces handling time and minimizes material loss during transport.

Industrial Grapples

Industrial grapples feature heavy-duty construction designed for waste management and recycling operations. These attachments handle everything from metal scraps to construction debris with superior control compared to standard buckets. The precise gripping action allows operators to sort materials, load containers efficiently, and manage waste streams effectively.

Demolition contractors particularly value industrial grapples for their ability to extract specific materials from debris piles. Rather than scooping everything indiscriminately, grapples enable selective material handling that improves recycling rates and reduces disposal costs.

Augers: Precision Drilling for Multiple Applications

Auger attachments transform your skid steer into a powerful drilling machine capable of creating precise holes in various ground conditions. These hydraulically driven attachments use spiral cutting surfaces to bore through soil, clay, and even soft rock formations.

Standard Earth Augers

Standard earth augers handle most common drilling applications, including fence post installation, foundation pier holes, and tree planting. Available in diameters ranging from 6 inches to 36 inches, these attachments accommodate diverse hole size requirements. The spiral design efficiently removes soil from the hole while drilling, maintaining clean bore walls.

Landscaping professionals rely heavily on earth augers for installing irrigation systems, planting large trees, and creating drainage solutions. The consistent hole diameter and clean cutting action reduce manual finishing work and ensure proper fit for installed components.

Heavy-Duty Rock Augers

Rocky terrain and challenging soil conditions require specialized auger designs. Heavy-duty rock augers feature carbide cutting teeth and reinforced construction that can penetrate difficult ground conditions. These attachments cost more than standard earth augers but prove essential for projects in rocky areas where standard augers fail.

Utility installation projects often encounter varying ground conditions that demand rock auger capabilities. The ability to drill through both soil and rock formations with a single attachment eliminates the need for multiple specialized tools.

Specialty Augers

Specialty augers address unique drilling requirements that standard attachments cannot handle. Ice augers create holes in frozen ground or ice surfaces, while tree augers feature specific designs optimized for root ball installation. These specialized attachments serve niche markets but provide essential capabilities for specific applications.

Maximizing Your Skid Steer Investment

The versatility of skid steer attachments represents one of the strongest arguments for investing in these machines. A single skid steer equipped with multiple attachments can replace several specialized pieces of equipment while requiring less storage space and maintenance resources.

Consider your most common applications when selecting attachments, but don’t overlook the value of versatility. Many contractors discover that attachment capabilities open new revenue opportunities they hadn’t previously considered. The ability to handle diverse projects with existing equipment improves cash flow and expands your service offerings.

Quality attachments require significant investment, but they deliver value through improved productivity and expanded capabilities. Research attachment manufacturers carefully, considering factors like warranty coverage, parts availability, and local dealer support. The lowest purchase price rarely represents the best long-term value when maintenance and downtime costs are factored into the equation.

Regular maintenance extends attachment life and ensures reliable performance. Follow manufacturer recommendations for hydraulic fluid changes, lubrication schedules, and cutting-edge replacement. Proper maintenance practices protect your investment while minimizing costly repairs and unexpected downtime.

Your skid steer’s attachment system opens unlimited possibilities for tackling diverse projects efficiently. Whether you choose buckets for material handling, grapples for precision work, or augers for drilling applications, the right attachments transform your machine into the exact tool your project demands.